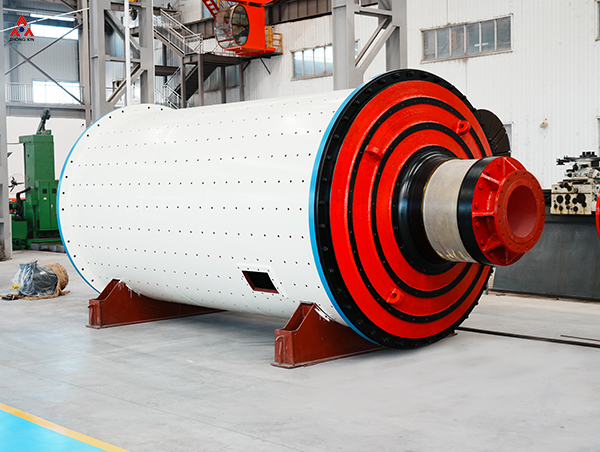

When assessing whether a

ball mill is operating at its optimal condition, several factors need to be considered. First, appropriate operating parameters are crucial for grinding efficiency. For example, rotational speed and feed rate need to be adjusted according to actual conditions to maximize energy utilization and ore crushing effectiveness.

Secondly, monitoring grinding efficiency is crucial, which can be effectively assessed by analyzing the particle size of the finished product and raw materials. Furthermore, the noise and vibration levels of the equipment are important indicators for evaluating its health. Under normal circumstances, the equipment should emit a stable and uniform sound, while abnormal noise or vibration may reveal potential problems.

Therefore, by comprehensively analyzing operating parameters, grinding efficiency, and noise and vibration levels, it is possible to accurately determine whether the ball mill is operating at its optimal condition, providing a solid basis for equipment maintenance and production.

Leave Message

Leave Message Chat Online

Chat Online