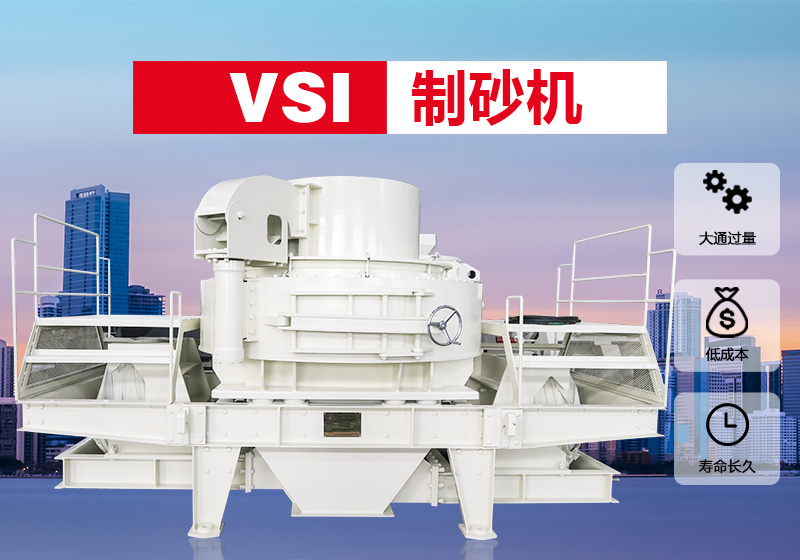

Type:Secondary Crushing

Capacity:90-1200 TPH

Applications:Aggregates Shaping, Mechanism sand, Bituminous Concrete, Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy

Power:132-630KW

Processed Materials:Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore, Manganese Ore, etc. (for Hard Stone).

Email:

sales@zxcrusher.comWhatsapp/Wechat:

+86-13676922906![]() WhatsApp

WhatsApp

![]() Wechat

Wechat

Tel:0086-371-67660555

Email:sales@zxcrusher.com

Skype:zxcrushers@outlook.com

Whatsapp:+86-13676922906

Scan the QR code of Zhongxin Heavy Industry,add friend.

Hydraulic Cone Crusher not only improves the production capacity and crushing efficiency, but also widens the applying area, from limestone to basalt, from stone production to various ore crushing. It has crushing performance in the work of medium-size crushing, fine crushing.

Hydraulic Cone Crusher Features:

1.Production capacity;

2.crushing principle, performance;

3.Capacity of product;

4.Replace crushing cavity if you need medium,fine,and super fine product;

5.Can be installed on the steel structure or concrete foundation in the workshop or open area;

6.Low operating and maintenance cost;

7.Short downtime and long working hours;

8.Easy operation and easy to maintain;

9.Multiple protection,avoid accidents and damage caused by human incorrect operation.

When XHP seriesmulti-cylinderhydraulic cone crusher works, the motor drives the outer copper rotate through V-belt, host pulley, drive shaft, a small bevel gear, a large bevel gear. The outer copper forces crushing cone shaft axis of the outer copper to make rotating swing, making crushing surface.

Sometimes near and sometimes leave the concave surface, so that the material is impacted, squeezed and bent in the ringlike crushing chamber consist of fixed cone and movable cone. After repeated squeezed, shocked, and bent, the material crushing to the required particle size is discharged from the lower part.

The particular crushing chamber adopting principle of intergranular lamination and matching rotor speed obviously improves the crushing ratio and productivity, largely increase the amount of cubic final product.

Adopting hydraulic protection and hydraulic cavity clearing, high degree of automation, the hydraulic system can be up top and discharge automatically when the crusher is blocked instantly or over-iron, which eliminates trouble of halting to clear the material manually.

It makes the maintenance easy, cost low. The hydraulic adjustment and oil lubrication make the crusher steady and reliable. It also adopts labyrinth sealing mode, which avoids oil mixing with water easily.

|

Model |

Cavity |

Standard Type |

Short Type |

Power |

Capacity (t/h) |

Weight(t) |

||

|

Feeding Size (mm) |

Min Discharging Size (mm) |

Feeding Size (mm) |

Min Discharging Size (mm) |

(kw) |

||||

|

XHP200 |

Super coarse |

|

|

|

|

132-200 |

90-250 |

14 |

|

Coarse |

185 |

19 |

76 |

10 |

||||

|

Medium |

125 |

17 |

54 |

6 |

||||

|

Fine |

95 |

13 |

23 |

6 |

||||

|

Super Fine |

|

|

10 |

5 |

||||

|

XHP300 |

Super coarse |

230 |

25 |

|

|

180-250 |

115-440 |

19.96 |

|

Coarse |

210 |

20 |

75 |

10 |

||||

|

Medium |

150 |

15 |

50 |

8 |

||||

|

Fine |

105 |

10 |

20 |

6 |

||||

|

Super Fine |

|

|

20 |

6 |

||||

|

XHP400 |

Super coarse |

295 |

30 |

|

|

280-355 |

140-630 |

28.72 |

|

Coarse |

250 |

25 |

90 |

10 |

||||

|

Medium |

195 |

20 |

50 |

8 |

||||

|

Fine |

110 |

14 |

40 |

6 |

||||

|

Super Fine |

|

|

30 |

6 |

||||

|

XHP500 |

Super coarse |

330 |

30 |

|

|

355-450 |

175-790 |

38 |

|

Coarse |

285 |

25 |

90 |

13 |

||||

|

Medium |

200 |

20 |

55 |

10 |

||||

|

Fine |

133 |

16 |

40 |

8 |

||||

|

Super Fine |

|

|

35 |

6 |

||||

|

XHP800 |

Super coarse |

353 |

32 |

|

|

550-630 |

260-1200 |

64.1 |

|

Coarse |

297 |

32 |

160 |

13 |

||||

|

Medium |

250 |

25 |

100 |

10 |

||||

|

Fine |

220 |

16 |

50 |

5 |

||||

|

Super Fine |

|

|

|

|

||||

Leave your needs, Our sales manager will contact with you as soon as possible.

TEL:0086-371-67660555

E-mail:sales@zxcrusher.com

Whatsapp/Wechat:+86-13676922906

Chinese website:www.jzzxzg.com

English website:www.zxcrusher.com

España:www.zxcrusher.es Русский:www.zxcrusher.ru